Nitrates In Drinking Water

- Nitrates can get into groundwater from many sources, including fertilizers, manure on the land, and liquid waste discharged from septic tanks.

- Natural bacteria in soil converts various forms of nitrogen into nitrate.

- Rain and irrigation water can carry nitrate down through the soil into groundwater.

- Nitrate contamination of drinking water is a growing concern since it can cause serious health risks.

- In the 1990s, the USEPA’s set the maximum contaminant level (MCL) for nitrate needed to protect against blue-baby syndrome at 10 mg/l.

Product Description & Features

EMCO Nitrate Removal Systems based on Ion Exchange Resin are an excellent choice for the removal of Nitrate from potable water applications. The system is based on a Brine Regenerable – Strong Base resin that’s exchanges nitrate ions for chlorides and its performance far exceeds the current EPA MCLs, allowing for some blending that extends the resin bed cycle times.

All EMCO’s Ion Exchange IX systems for Nitrate removal have the following Features:

- Fully on-site regenerable with brine makers and water softeners.

- Optimized Layout and Expandable design allowing for easy capacity increase.

- High selectivity resin for nitrates compared to other competing ions (sulfates, bicarbonates..)

- Fully Automated System with Customized Operation to Suit the End User’s Needs.

- All our vessels are ASME Stamped with NSF approved coating.

- Manufactured in the US with the option to manufacture it overseas.

- Separate Regenerant Distributor to Optimize the regeneration Process

- Increase Water Recovery to Reduce the Wastewater Generated.

Disclaimer

Smooth operation of the resin system is dependent on influent water quality. Specific pre-treatment requirements are to be met (refer to manufacturer for more details)

Technical Information

Vessel

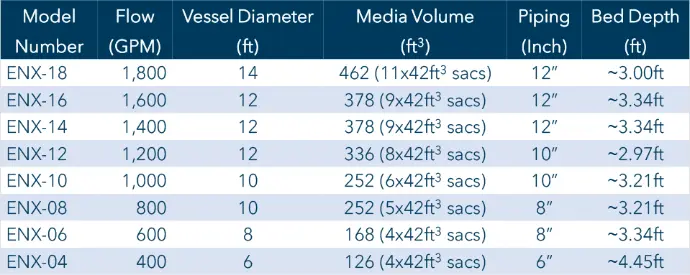

Vessel Diameter: up to 12-14ft

Flow per Vessel: up to 1,800.00 gpm

Design Pressure: Based on Hydraulic Design (up to 145psi/10Bars)

Vessel Configuration: Duty/Standby

Operation: Fully Automatic

Material of Construction: Carbon Steel (Coated) – Stainless Steel is Optional

Vessel Protection: NSA Approved Pressure Relief Valve

Manufacturing Code: ASME Code VIII (Stamped)

Face-piping Valves: Automatic Butterfly Valves with Manual Handwheel

(Local Actuator Control Station OPTIONAL)

Valve Actuation (if Any): Electric Actuators

Optional – Pneumatic Actuator (if compressed air is available at site)

Water Distributor/Collector: Header & Laterals / Septa Design or Drop Header & Laterals

System Appurtenances: Brine Maker, Water Softener, Pre-Treatment (Refer to Vendor)

Customization Treatment System can be Customized to suite various configurations and capacities. Going with the standard sizes above, or multiple smaller sizes for the same capacity is always an option. Reach out to our experts and they will gladly support your project.

Resin Media

Type: Strong Base Anion Resin

Polymer Structure: Gel Polystyrene crosslinked with divinylbenzene

Media Appearance: Spherical Beads

Functional Group: Type I Quaternary Ammonium

Beads Mean Diameter: 570 ± 50μm

Shipping Weight: 42.2 – 44.0 lb/ft3 (670 – 700 g/L)

Resin Form: Chloride Form

Regulatory Approvals: Certified by the WQA to NSF/ANSI-61 Standard

Note

A low profile is available to meet strict height restrictions, especially for wells residential areas or for equipment to be installed inside existing buildings with limited height access.