Per & Poly-Fluoro Alkyl Substances PFAS

- Group of chemicals used to make fluoropolymer coatings and products that resist heat, oil, stains, grease, and water.

- They are called the forever chemicals because they do not break down in the environment.

- Found in the blood of people, animals and in a variety of food products and in the environment.

- Exposure to some PFAS may be linked to harmful health effects in humans and animals.

- In March 2023, the Environmental Protection Agency EPA issued new guidelines lowering the drinking water maximum contaminant levels (MCLs) for PFOA and PFOS to 4ppb (parts per billion) necessitating its removal from all drinking water applications.

Product Description & Features

EMCO PFAS Removal Systems based on adsorption on Granular Activated Carbon GAC media are a simple and cost-effective choice for the removal of PFAS from potable water applications. The system allows PFAS molecules, mainly long chain PFAS structures, to adsorb on carbon media allowing potable water treatment facilities to meet the current EPA guidelines.

All EMCO’s GAC Adsorption systems for PFAS removal have the following Features:

- High porous media with large quantity of adsorption sites with resiliency to background organics.

- Retrofittable system to that can be operated with GAC or IX resins.

- Backwashable media leading to Less TSS Pre-Treatment requirements.

- All our vessels are ASME Stamped with NSF approved coating.

- Manufactured in the US with the option to manufacture it overseas.

- Underdrain Design Flexibility with Drop Header & Lateral or Septa.

Under-drain system for ease of media unloading.

Disclaimer

Smooth operation of the resin system is dependent on influent water quality. Specific pre-treatment requirements are to be met (refer to manufacturer for more details)

Technical Information

Vessel

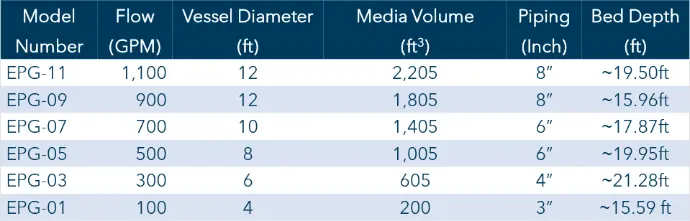

Vessel Diameter: up to 12-14ft

Flow per Vessel: up to 1,100.00 gpm

Design Pressure: Based on Hydraulic Design (up to 145psi/10Bars)

Vessel Configuration: Lead/Lag

Operation: Manual (OPTIONAL: Automatic)

Material of Construction: Carbon Steel (Coated) – Stainless Steel is Optional

Vessel Protection: NSA Approved Pressure Relief Valve

Manufacturing Code: ASME Code VIII (Stamped)

Face-piping Valves: Butterfly Valves with Handwheel (OPTIONAL: Automatic)

Valve Actuation (if Any): Electric Actuators

Optional – Pneumatic Actuator (if compressed air is available at site)

Water Distributor/Collector: Header & Laterals / Septa Design or Drop Header & Laterals

Sampling Ports: 3nos. (at 25%, 50% and 75% of media bed depth)

GAC Media

Media Base: Lignite or Bituminous Coal Media

Iodine Number: min. 1,000 mg/g

Abrasion Number (AWWA): min. 75

Moisture: 2.0% max. (as packed)

Mesh Size: 12 x 40 US mesh (1.7 to 0.42mm)

Greater than 12 mesh (1.70mm) 5.0% max.

Less than 40 mesh (0.42mm) 4.0% max.

Apparent Density: 31 lb/ft3 (0.49 g/mL) – Vibrating Feed

Bed Density: 27 lb/ft3 (0.42 g/mL) – Backwashed & Drained

Effective size: 0.7 mm

Uniformity Coefficient: 1.6

Empty Bed Contact Time: 15 minutes contact time (range from 10 to 20min)

Regulatory Approvals: Meets AWWA B100 and B604 standards for potable water use.

Meets NSF/ANSI Standard 61.

Note

A low profile is available to meet strict height restrictions, especially for wells residential areas or for equipment to be installed inside existing buildings with limited height access.